Fabrication

The MoCap marker consists of:

3D printed body (nut part and bottom part)

Reflective tape segments

One M4 nut

Qualisys underwater markers have diameters of 14 mm and 19 mm. This design replicates both sizes.

Since the reflective tape increases the diameter by approximately 1 mm, the printed parts are designed with diameters of:

13 mm → final 14 mm marker

18 mm → final 19 mm marker

The following steps describe the 19 mm version. The 14 mm version is identical.

3D Printing

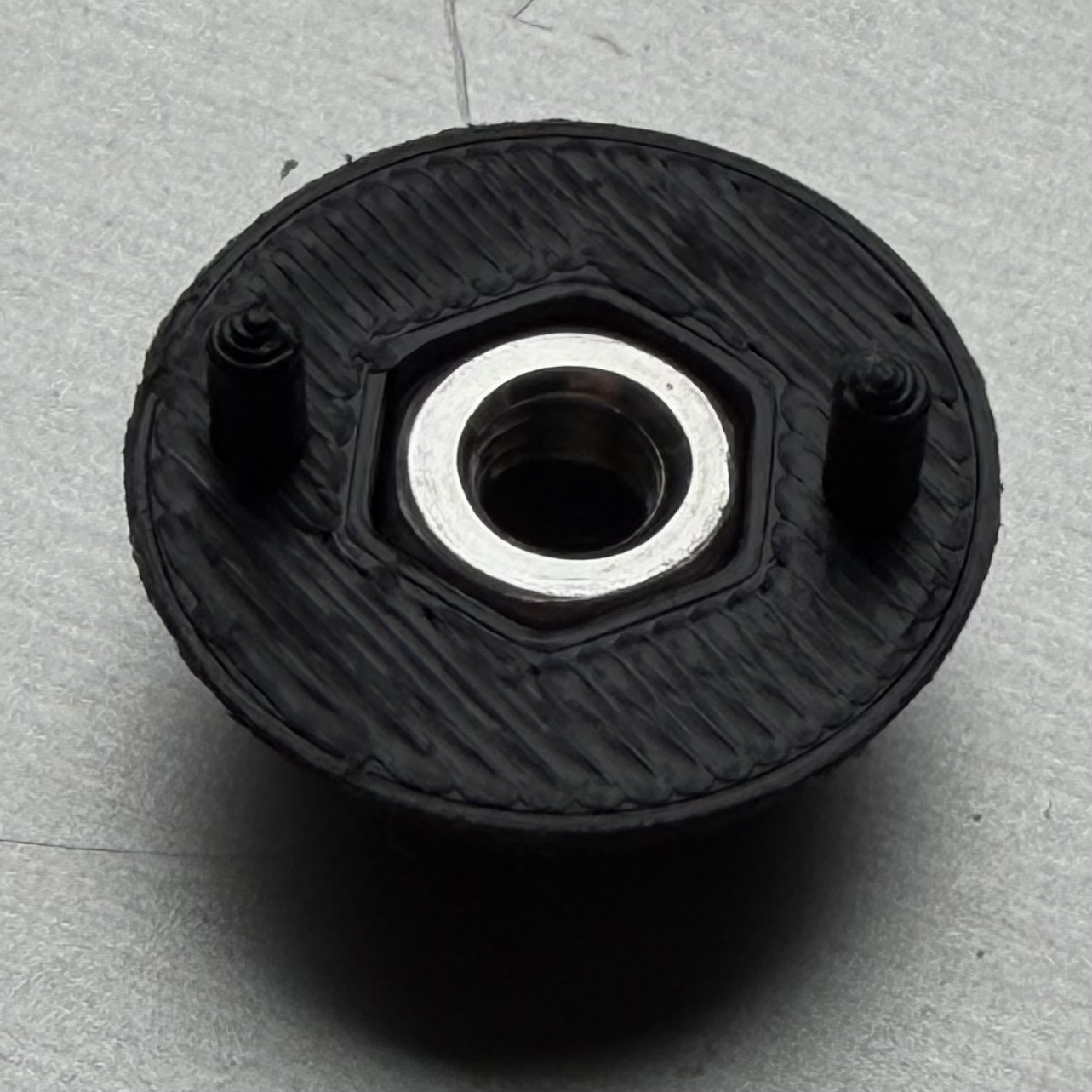

Print the nut part and bottom part shown in Fig. 11.

Fig. 11 3D printed nut part (left) and bottom part (right).

Assembly

Insert an M5 nut into the nut part (left image in Assembly images).

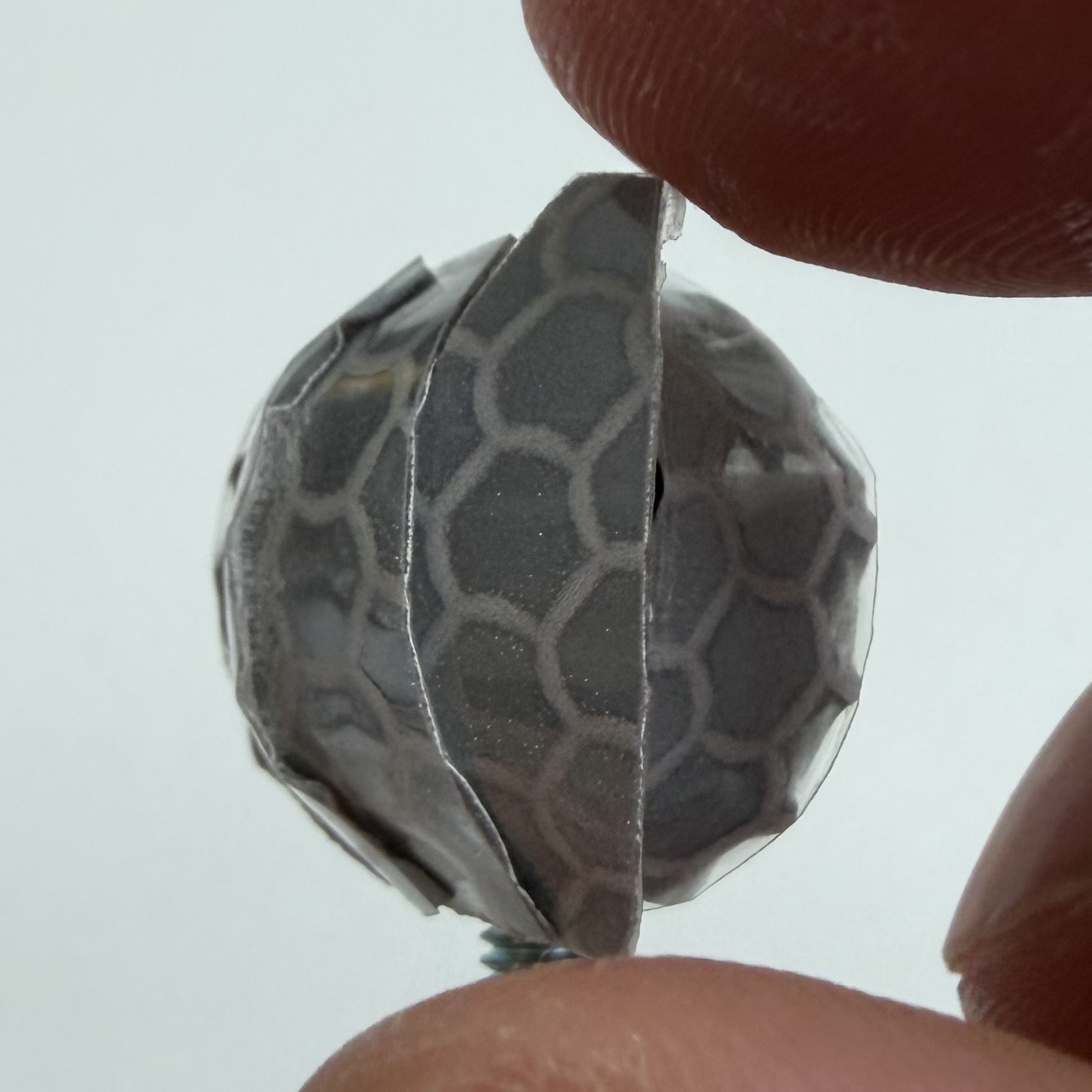

Press the nut part and bottom part together firmly (right image in Assembly images).

If the fit is loose, apply a small amount of adhesive between the parts.

Assembly images

(a) M4 nut inserted into the nut part.

|

(b) Parts pressed together.

|

Surface Preparation

Sand the outer surface to improve adhesion.

Tip

Screw the marker onto an M4 set screw, clamp the set screw in a drill, and rotate the marker while holding sandpaper against it.

Reflective Tape Application

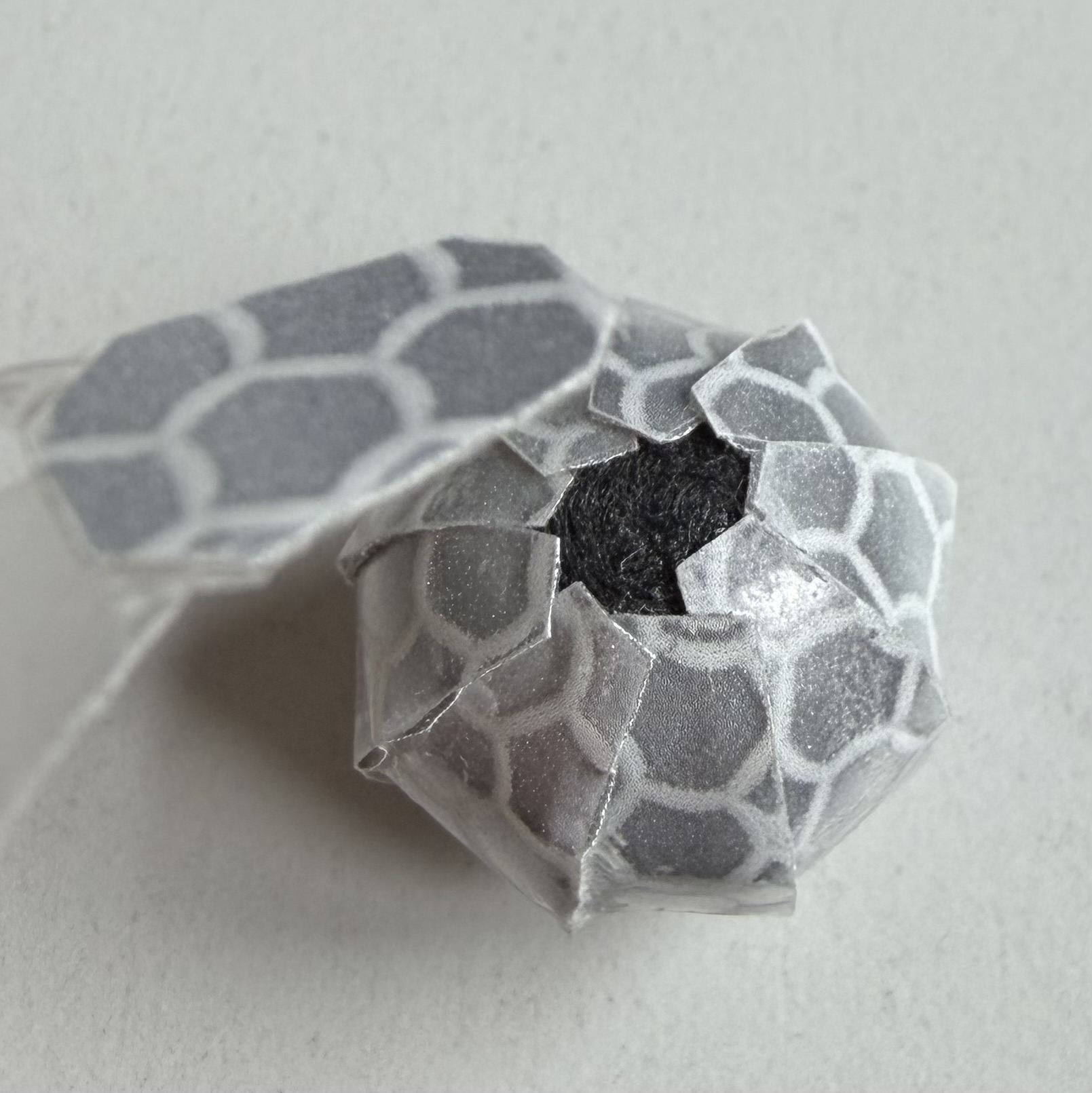

The following steps describe the application of the reflective tape. A visual summary of the process is shown in Reflective tape application steps.

The tape cannot be wrapped around the marker in one piece. Apply multiple segments in a globe-like pattern.

Cut the tape using the template. The exact shape is not critical, but one end should be narrower. Approximately nine segments are required.

For the first segment, remove the backing only halfway and press it onto the marker.

Attach the remaining segments one by one. Align the wider end with the lower edge of the nut part.

Apply the segments with slight overlap.

Before placing the final segment, remove the remaining backing from the first segment.

Slide the last segment underneath the first segment.

Cover the top with a small circular piece for a clean finish.

Note

The tape adhesive alone is usually insufficient for long-term use. Apply a small drop of superglue under each segment.

Attention

Do not allow superglue to contact the reflective surface. It may damage the coating and reduce tracking quality.

Reflective tape application steps

(1)

|

(2)

|

(3)

|

(4)

|

(5)

|

(6)

|

(7)

|

(Note)

|

Final Mounting

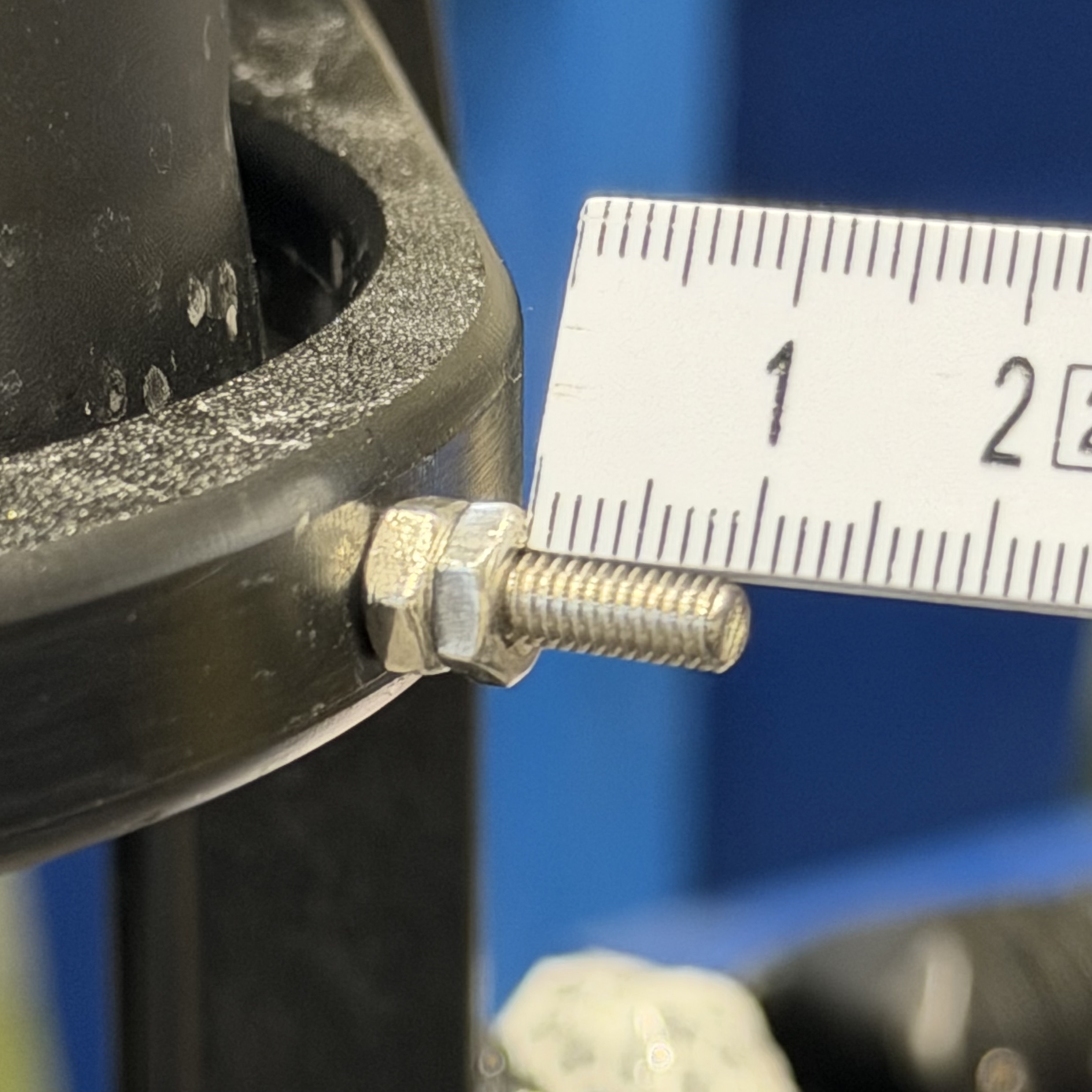

Screw the M4 set screw into the BlueROV frame.

Lock it in place using two counter-tightened nuts, as in Fig. 12.

Screw the finished marker onto the set screw until it is firmly seated.

Attention

Make sure the set screw does not stick out too far. Aim for approximately 10 mm. Otherwise, it may push the printed parts apart while tightening the marker.

Fig. 12 Set screw installed in BlueROV frame.